Artificial Lift Systems

Artificial lift refers to methodology of producing fluids from a well to surface once the well is no longer capable of producing by itself. Artificial lift is needed in wells when there is insufficient pressure in the reservoir to lift the produced fluids to the surface but can also be used in naturally flowing wells to increase the flow rate above what can produce through natural flow.

NILA GeoSolutions provides a host of Artificial Lift solutions as covered in this section.

Cutting Edge (ESP) Electrical Submercible Pumps & Equipment for any Downhole Environment

NILA Geo Solutions has an unmatched portfolio of innovative ESP solutions which automatically gives you access to industry specialists to assist you in overcoming the most technical challenges. We can advise you on the best artificial lift solutions throughout the lifecycle of your well and then keep them operating at peak performance to deliver the production rates you expect at the lowest possible lifting costs.

NILA GS has the ability to provide a wide range of quality ESP Lift solutions.

Standard Electrical Submersible Pumping (ESP)

Our standard electrical submersible pumping (ESP) systems use asynchronous motors and submersible pumps to lift fluid and gas from the reservoir to the surface. They are typically designed for moderate to heavy flow rates and come in a wide range of sizes.

In addition to our standard ESP, NILA GeoSolutions offers a full suite of application-specific equipment to meet your ESP needs. We strive to offer innovative tools that create more value for oil and gas production companies.

SLIMLINE ESP SYSTEMS

SlimLine ESP systems use a permanent magnet motor and high-efficiency pump stages to produce wells with casing sizes as small as 4 and 4.5 in. (102 and 114 mm). Available in 2.72-in. (69-mm) and 3.19-in. (81-mm) sizes, our SlimLine systems are ideal for use in wells with high dogleg severity and when accessing sidetrack laterals. Built on proven PowerSave ESP system technology, these slim ESPs reduce power consumption by 25–30% compared to the most efficient ESPs driven by induction motors.

Ξ Glide through deviations in 4 and 4.5-in. casing

Ξ Industry-leading OD and ESP length make running in hole easy

Ξ Easily access sidetracks, produce inside the curve

POWERSAVE ESP SYSTEMS

The PowerSave ESP System combines proprietary pump-stage design, precision parts manufactured using powder metallurgy, and advanced permanent magnet motor (PMM) technology to lower electrical submersible pumping (ESP) system power consumption by 25–30% or more. Reducing your electrical consumption is an effective way to reduce your carbon emissions. Our PowerSave ESP System reduces ESP length by 60%.

COLIBRI CABLE-DEPLOYED RIGLESS ESP

The Colibri rigless ESP system requires only reinforced carrying cable to be deployed and retrieved. All operations can be conducted on modified slickline equipment. There is no need for a rig, making it a truly rigless electrical submersible pumping (ESP) system. Saving both time and money, cable deployment enables operators to resume production quickly without having to kill the well. The short-term result is a decrease in deferred production without having to wait and pay for the rig required in standard ESP operations. The long-term implications include eliminating rigs from ESP installations altogether, reducing risk, and lowering the number of personnel required to install ESPs.

Ξ Eliminate the rig during ESP deployment, removal

Ξ Simple cable deployment eliminates the cost, time, and personnel needed for a rig

PERMANENT MAGNET MOTORS

Our permanent magnet motor (PMM) is the preferred motor in the artificial lift industry for electrical submersible pumping (ESP) systems. These powerful motors are the most reliable, robust, and energy efficient motors available with the widest range of available sizes and horsepower options.

our ESP Permanent Magnet Motors are powerful, efficient, and relentless.

Ξ Proven, rugged PMMs run cooler, longer, and through more gas slugs than induction motors.

Ξ Glide through 4½-in. and 5-in. casing to produce oil where other ESPs can’t fit.

The Next Generation of Progressing Cavity Pumps

Looking for a high-quality, low-cost pump? Explore our new line of progressing cavity pumps (PCP). Our streamlined products line of pumps are designed by the most reputable and pioneering minds in PC pumping technology Lifting Solutions

All Lifting Solutions product solutions are designed and manufactured in Canada, by a team of specialists using proven industry knowledge and experience. With the support of our partner Lifting Solutions, NILA GS is focused on supporting you with you next-generation project and flawless execution.

Benefits

Ξ Direct threaded stators to reduce costs and to avoid welds that are potential failure locations.

Ξ Fit-for-purpose geometries to accommodate common casing and tubing sizes without the requirements for

special accessories

Ξ Manufactured using new, modern technology and efficient practices in a PCP-dedicated manufacturing

facility for a low-cost, high-quality product

Gas Lift System

World-Class Gas Lift Design, Installation and Service

NILA GS, the leaders in highly accurate downhole data collection and monitoring are now putting that experience into World-Class gas lift design, installation and service.

NILAGS delivers comprehensive Artificial Lift Solutions to enhance production. With focus on providing cost-effective and reliable Gas Lift offering, we have entered into partnership with one of the largest manufacturer Gas Lift. All our Gas Lift products are manufactured in-house at our OEM state-of-the art manufacturing facility located in the USA.

We offer Gas Lift Valves and Mandrels in different metallurgy and configuration to cater to wide range of well conditions and gas lift design.

Our NILAGS Orion family of Conventional Gas Lift Valves and Mandrels offers cost effective solution to customer.

Our NILAGS Sirius family of Wireline Retrievable Gas Lift Valves and Side Pocket Mandrels provide customer flexibility to deploy various valves type over life of the well. NILAGS offers various accessories such as Dummy Valves, Check Valves, Latches, Running Tools, Pulling Tools and Kickover Tools.

NILAGS Orion Conventional & Valves and Mandrels

NILAGS Sirius Retrievable Valves and Mandrels

» NILAGS GLV Conventional Gas lift Valve (IPO)

» NILAGS GLM Conventional Gas Lift Mandrel

» NILAGS PO Conventional Pilot Operated Valve

» NILAGS CV Conventional Check Valve

» NILAGS CI Conventional Chemical Injection Valve

» NILAGS (R) GV Retrievable Gas Lift Valve (IPO)

» NILAGS (R) PO Wireline Retrievable Pilot Operated Valve

» NILAGS (R) DV Retrievable Dummy Valve

» NILAGS (R) OV Retrievable Orifice Valve

» NILAGS (R) GM Side Pocket Mandrel

NILAGS Ursa Water Injection Valves and Mandrels

Accessories

» NILAGS Ursa IV Water Flood Injection Valve

» NLAGS Ursa CV Water Flood Check Valve

» NILAGS Ursa IM Water Flood Injection Mandrel

» NILAGS SJD Pulling Tool

» NILAGS SBK, SRK Wireline Retrievable Latches

» NILAGS SRT Running Tool

» NILAGS SKT Kickover Tool

Horizontal Pumping System

Novomet surface pumps use technology developed for downhole electrical submersible pumping (ESP) systems to deliver reliable, low-maintenance pumps that help customers control costs.

We install centrifugal and multiphase pumps and offer fully mobile systems with the HPS skid and variable speed drive mounted on a trailer.

While multiple companies offer surface pumps, Novomet HPS have the added benefit of being able to handle high volumes of gas—up to 97% free gas volume.

Our surface pump benefits

Ξ Control upfront costs and reduce maintenance spend

Ξ Avoid downtime with a modular system that is easy to repair

Ξ Reduce environmental impact with fewer leaks and emissions

Ξ Effectively pump fluids with up to 97% of gas

Applications

Our surface pumps can be used across a wide range of upstream, midstream, and industrial applications including:

Ξ Injection wells

Ξ Surface fluid transfer

Ξ Pipeline boosting

Ξ High-pressure pumping

Ξ Mine dewatering

INSTALLATION & FIELD SERVICES

We believe that your success depends on ensuring your installation is supported by our eminently capable Field Engineers and Field technicians.

Additional Well Performance Optimization

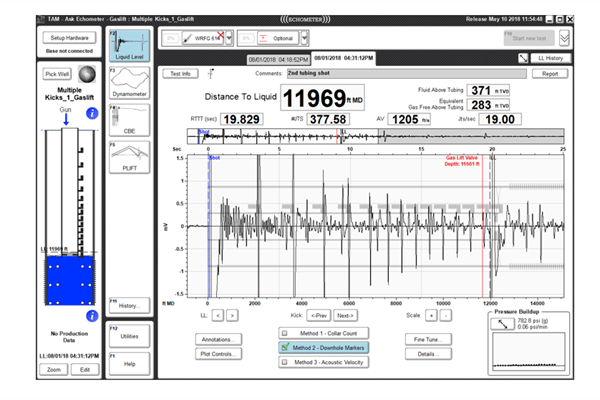

NILA GeoSolutions leverages the industry’s top tools such as Echometer Model E Well Analyzer and NR Tec Smart Shots to provide timely and accurate testing results at highly competitive rates. The Echometer Model E Well Analyzer is a rugged and reliable integrated artificial lift data acquisition and diagnostic system that maximizes:

Ξ Well productivity

Ξ Reservoir pressure

Ξ Well performance

By measuring:

Ξ Surface pressure

Ξ Overall efficiency

Ξ Power and pressure transient response

Our field technicians are skilled in all aspects of Acoustic Measurement, experienced in Fluid Level Determination, and committed to safety, ensuring top quality optimization services.

Acoustic Measurement for Fluid Level Determination

Ξ Is there liquid above the pump? At what depth is the top of the liquid column?

Ξ Is gas flowing up the annulus? If yes, at what rate?

Ξ What is the casing-head pressure? Is it changing with time?

Ξ What is the percent liquid in the annular fluid column?

Ξ What is the pressure at the perforations?

Ξ What is the percent of the maximum oil rate that is currently being produced?

Ξ What is the maximum rate that could be produced from the well?

Ξ What is the sound speed in the annular gas?

Ξ What is the average gravity of the gas in the annulus?

Ξ Are there any restrictions or anomalies in the annulus above the liquid level?